"Be Ambitious! Seek the inspiration to bring happiness to humanity through your work in PV."

"Be Ambitious! Seek the inspiration to bring happiness to humanity through your work in PV."

Since those closing words from the 17th International Photovoltaic Science and Engineering Conference (PVSEC-17) General Chairperson Professor Masafumi Yamaguchi (Toyota Technological Institute), the information packed Closing Address and Opening Address presentations have been uploaded to the PVSEC-17 Program page.

1439 Conference participants from around the world converged on the Fukuoka International Congress Center in Fukuoka, Japan, from December 3-7, 2007, for the 17th International Photovoltaic Science and Engineering Conference (PVSEC-17). The PVSEC-17 Conference was dominated by Japan with 769 participants while the top six (6) was rounded out by Korea 182, Taiwan 123, USA 95, Germany 74, and China 22. The simultaneous PVSEC-17 Exhibition featuring 46 Exhibitors attracted 5027 visitors over the course of 3 days.

During the PVSEC-17 Conference, 627 Papers from 36 countries were presented including about 364 Poster Presentations. Germany vaulted to third in Papers from their participant attendance rank of fifth. Chairperson Professor Yamaguchi noted the above trend ratio of Papers to Attendees for PVSEC-17 versus peer international photovoltaic conferences: EU PVSEC, IEEE-PVSC, and WCPEC.

First, here is an outline of the PVSEC-17 Conference Program by topic Area:

Area 1 Novel Materials and Devices

Area 2 III-V Materials and Devices for Concentrator and Space PV Systems

Area 3 Crystalline Silicon Solar Cells and Technologies

Area 4 Amorphous & Nano/Microcrystalline Silicon Based Solar Cells and Related Materials

Area 5 CIGS, II-VI and Related Thin Films and Cells

Area 6 PV Modules and System Components

Area 7 Terrestrial PV Systems

Area 8 PV Programs, Industries, Market, and Environment

Here are the links to Oral Sessions segmented by Conference day: December 3, December 4, December 5, December 6, and December 7.

Here are the Poster Sessions with focus topic Area(s):

Poster Session 1 Area 3, Area 7

Poster Session 2 Area 3

Poster Session 3 Area 5, Area 8

Poster Session 4 Area 2, Area 6

Poster Session 5 Area 1, Area 4

Poster Session 6 Area 1, Area 4

The Closing Address presentation includes:

Program Summary

Program Highlights

Awards Commendation Ceremony

Readers are directed to review the selected Program Highlights for themselves (Closing Address, pp. 7-15).

Below, I have included the Paper, Poster, and Young Researcher Award winners. Please note a number of Areas have co-winners.

Paper Awards

Area 1

4O-A3-02 SCANNING PROBE MICROSCOPE STUDY OF DYE-SENSITIZED TiO2(110)

A. Sasahara1,2, M. Ikeda1, N. Koide3, L. Han3 and H. Onishi1

1Kobe University, Japan, 2Japan Science and Technology Agency, Japan, 3Sharp Corporation, Japan

Area 2

6O-B11-03 DEVELOPMENT OF SPACE SOLAR SHEET

T. Kodama1, H. Yamaguchi1, N. Takahashi1, T. Agui1, H. Washio1, K. Nakamura1, T. Hisamatsu1,

T. Takamoto1, K. Shimazaki2, M. Imaizumi2 and K. Kibe2

1SHARP Corporation, Japan, 2Japan Aerospace Exploration Agency, Japan

Area 3

6O-M5-01 HIGH EFFICIENCY MULTICRYSTALLINBE SILICON BACK CONTACT SOLAR CELLS

N. Nakatani, T. Sakamoto, K. Fukui and K. Shirasawa

Kyocera Corporation, Japan

6O-M4-01 22%-EFFICIENCY HIT SOLAR CELL

Y. Tsunomura, Y. Yoshimine, M. Taguchi, T. Kinoshita, H. Kanno, H. Sakata, E. Maruyama and M. Tanaka

SANYO Electric Co., Ltd., Japan

Area 4

5O-B6-01 LIGHT SCATTERING EFFECTS OF HIGHLY TEXTURED TRANSPARENT CONDUCTIVE OXIDES FILMES

N. Taneda, M. Kambe, T. Oyama and K. Sato

Asahi Glass Co., Ltd., Japan

5O-B7-02 THIN FILM SOLAR CELLS BASED ON MICROCRYSTALLINE SILICON-GERMANIUM NARROW GAP ABSORBERS

T. Matsui1, C.W. Chang1, T. Takada1,2, M. Isomura2, H. Fujiwara1 and M. Kondo1

1National Institute of Advanced Industrial Science and Technology (AIST), Japan, 2Tokai University, Japan

Area 5

6O-A11-02 MASS-PRODUCTION TECHNOLOGY FOR CIGS MODULES

K. Matsunaga1, T. Komaru1, Y. Nakayama1, T. Kume2, and Y. Suzuki2

1Honda Engineering Co., Ltd., Japan, 2Honda Soltec Co., Ltd., Japan

Area 6

6O-A10-02 DIFFERENCE IN THE OUTDOOR PERFORMANCES OF BULK AND THINFILM SILICON BASED PHOTOVOLTAIC MODULES

T. Minemoto, S. Fukushige and H. Takakura

Ritsumeikan University, Japan

Area 7

5O-C8-01 PERFORMANCE OF GRID CONNECTED PV INVERTERS DURING DISTURBED GRID CONDITIONS - CURRENT STATE OF PLAY & RECOMMENDATIONS FOR OPTIMAL PRODUCT DESIGN

R. Bruendlinger, B. Bletterie and C. Mayr

arsenal research, Austria

Area 8

6O-C9-05 ENVIRONMENTAL POTENTIAL OF VERY LARGE SCALE PHOTOVOLTAIC POWER GENERATION (VLS-PV) SYSTEMS ON DESERTS

K. Komoto1, M. Ito2, N. Yamashita3 and K. Kurokawa3

1Mizuho Information & Research Institute, Inc., Japan, 2Tokyo Institute of Technology, Japan, 3Tokyo University of Agriculture and Technology, Japan

Poster Awards

Area 1

6P-P6-35 STRUCTURAL AND OPTICAL PROPERTIES OF PHOSPHORUS DOPED SILICON QUANTUM DOT SUPPERLATTICE FOR ALL SILICON TANDEM SOLAR CELL

X. Hao1, E. Cho1, G. Scardera1, E. Bellet2, D. Bellet2, S. Park3, G. Conibeer1 and M. A. Green1

1University of New South Wales, Australia, 2Laboratoire GPM2-ENSPG, France, 3Samsung Advanced Institute of Technology, Korea

6P-P6-28 USE OF ZNO NANOSTRUCTURE TOWARDS HIGH EFFICIENCY INORGANIC/ORGANIC HYBRID THIN FILM SOLAR CELLS

K. Takanezawa, K. Tajima and K. Hashimoto

The University of Tokyo, Japan

Area 2

5P-P4-14 FIELD TEST OF A GRID-CONNECTED 500X CONCENTRATOR PV SYSTEM WITH DOME FRESNEL LENS

Y. Kemmoku1, K. Araki2, Y. Miyazaki3 and M. Hiramatsu3

1Toyohashi Sozo University, Japan, 2Daido Steel Co., Ltd., Japan, 3Daido Metal Co., Ltd., Japan

Area 3

4P-P1-23 REAL-TIME OBSERVATION OF UNIDIRECTIONAL SOLIDIFICATION PROCESSES FOR HIGHER-QUALITY MULTICRYSTALLINE SILICON INGOTS

I. Yamaga, K. Yamada, N. Araki, H. Suzuki and T. Saitoh

Dai-Ichi Kiden Corp., Japan

4P-P2-33 ALTERNATIVES TO SCREEN PRINTING FOR THE FRONT SIDE METALLIZATION OF SILICON SOLAR CELLS

M. Alemán, N. Bay, A. Knorz, A. Grohe and S. W. Glunz

Fraunhofer Institute for Solar Energy Systems, Germany

Area 4

6P-P6-62 ELECTRICAL AND OPTICAL PROPERTIES OF HYDROGEN-TREATED ZnO:Al FILMS

S. Tark1, M. Kang1, S. Lee2, W. Kim2 and D. Kim1

1Korea University, Korea, 2Korea Institute of Science and Technology, Korea

Area 5

5P-P3-13 SOLVOTHERMAL SYNTHESIS OF COPPER INDIUM DISELENIDE WITH FACILE SOLUTION ROUTE

J. Chang, H. Nam, J. Han and D. Jung

Sungkyunkwan University, Korea

5P-P3-17 BIFACIAL CIGS THIN FILM SOLAR CELLS USING HIGH MOBILITY Ti-DOPED In2O3 BACK CONTACTS

T. Miyano, R. Hashimoto, Y. Kanda, T. Mise and T. Nakada

Aoyama Gakuin University, Japan

Area 6

5P-P4-36 EXPERIMENTAL STUDIES ON DETECTING A DISCONNECTION POSITION OF BETWEEN PV MODULES BY THE ELECTRIC CAPACITANCE MEASUREMENT

J. Yamaguchi1, T. Takashima2 and M. Ishida1

1University of Tsukuba, Japan, 2AIST, Japan

Area 7

4P-P1-48 RESEARCH ON THREE-DIMENSIONAL COORDINATES ACQUISITION FOR SHADOW ESTIMATION IN PHOTOVOLTAIC SYSTEM

Y. Watanabe and K. Krokawa

Tokyo University of Agriculture and Technology (TUAT), Japan

Area 8

5P-P3-76 FINANCING A VERY LARGE SCALE PHOTOVOLTAIC SYSTEM IN GOBI DESERT

K. Megherbi1, M. Ito2, F. D. Ferretti1 and K. Kurokawa3

1Dexia Credit Local, France, 2Tokyo Institute of Technology, Japan, 3Tokyo University of Agriculture and Technology, Japan

Young Researcher Awards

Area 1

5O-A6-03 ORGANIC THIN–FILM SOLAR CELL EMPLOYING A NOVEL ELECTRON-DONOR MATERIAL

H. Kanno, M. Shirakawa, D. Fujishima, T. Kinoshita, H. Sakata, E. Maruyama and M. Tanaka

Sanyo Electric Co., Ltd., Japan

Area 2

6O-B11-06 ANALYSIS OF SOLAR CELL DEGRADATION MECHANISM DUE TO ESD IN SPACE

T. Okumura1, K. Toyoda1, M. Imaizumi2 and M. Cho1

1Kyushu Institute of Technology, Japan, 2Japan Aerospace Exploration Agency, Japan

Area 3

4P-P2-15 A NEW METHOD FOR THE PRODUCTION OF ULTRA-THIN CRYSTALLINE SI WAFERS

F. Dross1, A. Milhe1,2, J. Robbelein1, I. Gordon1,P. O. Bouchard2, G. Beaucarne1 and J. Poortmans1

1IMEC, v.z.w., Belgium, 2Ecole des Mines de Paris (CEMEF), France

Area 4

5O-B7-04 6.3% EFFICIENCY SOLAR CELL EMPLOYING HIGH DEPOSITION RATE (8 NM/S) MICROCRYSTALLINE SILICON PHOTOVOLTAICLAYER

Y. Sobajima, M. Nishino, T. Fukumori, T. Higuchi, S. Nakano, T. Toyama and H. Okamoto

Osaka University, Japan

Area 5

4O-C4-02 PHYSICAL VAPOUR DEPOSITION OF COMPOUND INDIUM SULPHIDE AS BUFFER LAYER IN CU(IN,GA)SE2 SOLAR CELLS: MATERIAL CHARACTERISATION AND DEVICE PERFORMANCE

P. Pistor1, R. Caballero1, D. Hariskos2, V. Izquierdo-Roca3, R. Wächter4 and R. Klenk1

1Hahn-Meitner-Institut, Germany, 2Zentrum fuer Sonnenenergie-und Wasserstoff-Forschung, Germany, 3Universitat de Barcelona, Spain, 4Würth Solar GmbH & Co. KG, Germany

6O-A11-03 FABRICATION OF PENTANARY Cu(InGa)(SeS)2 ABSORBERS BY SELENIZATION AND SULFURIZATION

Y. Goushi, H. Hakuma, K. Tabuchi, S. Kijima and K. Kushiya

Showa Shell Sekiyu K.K., Japan

Area 6

6O-A10-03 AN LED-BASED PHOTOVOLTAIC MEASUREMENT SYSTEM WITH VARIABLE SPECTRUM AND FLASH SPEED

M. Bliss, T. R. Betts and R. Gottschalg

Loughborough University, UK

Area 7

5O-C6-03 ESTIMATING THE CAPACITY VALUE AND PEAK-SHAVING POTENTIAL OF PHOTOVOLTAICS IN ONTARIO: A CASE-STUDY FOR THE CITY OF TORONTO

S. Pelland1 and I. Abboud2

1CANMET Energy Technology Centre-Varennes, Canada, 2Environment Canada Experimental Studies Division ARQX, Canada

5O-C8-02 AN ANALYSIS OF ELECTRICITY COST OF PHOTOVOLTAIC SYSTEMS ON THE FIELD TEST PROJECT IN JAPAN

T. Oozeki1, T. Yamada1, K. Kato1 and T. Yamamoto2

1National Institute of Advanced Industrial Science and Technology, Japan, 2New Energy and Industrial Technology Development Organization (NEDO), Japan

Area 8

6O-C9-01 A PRELIMINALY LIFE-CYCLE ANALYSIS OF A MEGA-SOLAR SYSTEM IN JAPAN

M. Ito1, M. Kudo2 and K. Kurokawa3

1Tokyo Institute of Technology, Japan, 2NTT Facilities, Inc., Japan, 3Tokyo University of Agriculture and Technology, Japan

Alas, although I had begun the preparations for attending PVSEC-17, I was unable to get away that first full week in December. I believe I missed getting a sense of the Photovoltaic (PV) market vibe from Japan and the PV research underway in Japan and Asia.

Thanks are in order to Greentech Media, Nanosolar Chooses German Town for Solar Plant, and Earth2Tech, Nanosolar Starts Thin-Film Solar Panel Production, for linking to my In Search of Nanosolar GmbH post.

Labels: PVSEC-17

Advent Solar, Inc.

Advent Solar, Inc. Blue Square Energy

Blue Square Energy Concentrix Solar GmbH

Concentrix Solar GmbH Greentech Media

Greentech Media Izusu Glass Co., Ltd.

Izusu Glass Co., Ltd. Oerlikon Solar

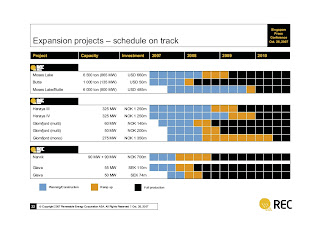

Oerlikon Solar REC Solar Grade Silicon LLC

REC Solar Grade Silicon LLCSolarvalue AG