Peak Sun Silicon: Polysilicon from Oregon

As of late, Peak Sun Silicon Corporation has been basking in the peak Intersolar North America 2008 and Oregon news with:

- Solar Jobs Rising in Oregon by Richard Read, The Oregonian

- Intersolar NA CNET Interview by Elsa Wenzel, CNET News.com

- Sun Sun Sun, Here it Comes by Ben Jacklet, Oregon Business

I learned more About Peak Sun Silicon when I ran into their stand at Intersolar in San Francisco.

Peak Sun Silicon will produce granular polysilicon utilizing a unique tribromosilane (SiHBr3) or TBS based continuous manufacturing process operating near atmospheric pressure and lower temperatures with improved energy efficiency. Per this Schumacher Bromosilane Process description:

The SBP process change from conventional polysilicon approaches is from an open-loop, batch, high temperature process, to a closed-loop (environmentally friendly), continuous, low temperature process. This innovation is accomplished by changing the silicon chemistry from a chlorine base to a bromine base (tribromosilane or "TBS"), and use of a "fluid bed" ("FB") deposition reactor with continuous recycle of by-products.

The Peak Sun Silicon Granular Feedstock Specification describes their Electronic Grade polysilicon with 10N (ten nines) purity as uniform dense spherical-bead sized 1mm granules perfect for continuous silicon solar wafer growth processes

On February 28, 2008, Peak Sun Silicon held a ground breaking ceremony for their new headquarters and polysilicon production facility located in Albany, Oregon, near Millersburg. Per the press release Peak Sun Silicon Breaks Ground on Polysilicon Facility in Millersburg, Oregon:

Phase I construction will include a 5,000 square foot chemical purification building and a 5,000 square foot electronics grade polysilicon processing building.

![]() Phase I is now expected to ramp 50 MT per year of pilot polysilicon production capacity in the first quarter of 2009 using tribromosilane produced on-site. Millersburg plant will make polysilicon for chips in solar panels reports the estimated construction cost is about $29 million, up from about $18 Million in Silicon maker picks Millersburg site and will employ 50 workers to start. As part of Peak Sun Silicon Secures Series A Funding for Polysilicon Manufacturing Plant, the total amount of Series A funding is not disclosed, but the mix of debt, equity, and tax incentives includes a $14 million loan under the Energy Loan Program administered by the Oregon Department of Energy.

Phase I is now expected to ramp 50 MT per year of pilot polysilicon production capacity in the first quarter of 2009 using tribromosilane produced on-site. Millersburg plant will make polysilicon for chips in solar panels reports the estimated construction cost is about $29 million, up from about $18 Million in Silicon maker picks Millersburg site and will employ 50 workers to start. As part of Peak Sun Silicon Secures Series A Funding for Polysilicon Manufacturing Plant, the total amount of Series A funding is not disclosed, but the mix of debt, equity, and tax incentives includes a $14 million loan under the Energy Loan Program administered by the Oregon Department of Energy.

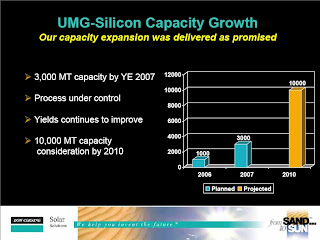

In Phase II, Peak Sun Silicon plans to ramp polysilicon production capacity to 5000 MT per year in 2012 and bring online an additional 5000 MT per year capacity in 2013 for a total of 10000 MT per year. Peak Sun Silicon expects Phase II will require $700 million in capital investment and increase employment to about 500.

Patents and Process advantages

While the original Schumacher Bromosilane Process patent is over 30 year old:

United States Patent 4,084,024 April 11, 1978

“Process for the production of silicon of high purity”

a newer patent invented by Lloyd Woerner and Edward Moore for the J.C. Schumacher Company innovated the low temperature, closed loop process:

United States Patent 4,318,942 March 9, 1982

“Process for producing polycrystalline silicon”

Additional process reports are available from the NASA Technical Reports Server (NTRS):

The production of solar cell grade silicon from bromosilanes

Closed-Loop Process Yields Ultrapure Silicon (abstract only)

According to the Peak Sun Silicon presentation by President and CEO John C. Schumacher, Ph.D. (see Resume), at the Photon Expo in Munich, Germany, on April 2, 2008, the Schumacher Process for producing silicon has the following advantages:

- Environmentally sound -- effluent recycled 100%

- Low carbon emissions – 61 pounds CO2/kg

- Energy efficient – 50kWh/kg total heat load (“THL”)

- Low temperature – 850 oC maximum

- High Yield – dust free

- Efficient use of materials -- closed loop process

- Zero explosive polymer formation in exhaust

- Fluid Bed Product & Synthesis Reactors

- High purity – raw material impurities purged from recycle

Peak Sun Silicon also manufactures high purity Phosphorus Oxychloride (POCl3) used as an N-Type dopant for silicon solar wafers.

The Solar Jobs Rising in Oregon article tips three big solar companies are considering the Oregon Solar Forest for manufacturing facilities and one existing company is planning an expansion. Code names Project Ark (Sanyo?), Project Harvester, and the big one Project Tahoe are used to disguise solar companies considering Oregon for manufacturing sites.

Labels: Peak Sun Silicon